Day One

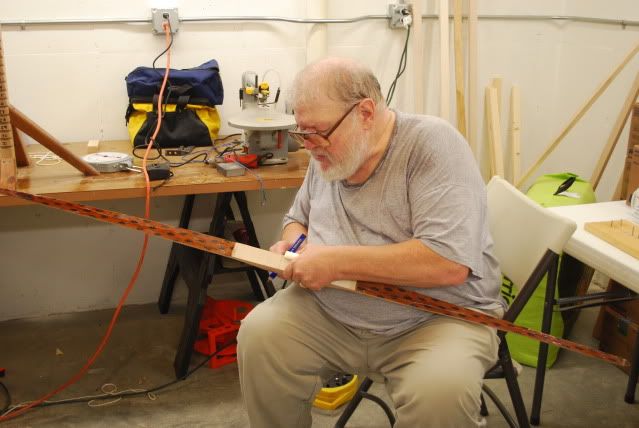

It started with wood selection and choosing the silk ties that would become the backing for the bows. Mere silk and sticks now, soon to be bows!Layout was first, measure twice and cut once the rule. Unfortunately one of the staves became the first casualty on cutout when the blade drifted over the well measured line. No big deal though, plenty of supplies on hand.

After the cut out, the sanding began. Sanding, sanding and more sanding! After plenty of hard work, the backs of the bows were shaped and sanded and ready for the glue up.

Silk ties cut apart, handle materials chosen and lots of sloppy glue work.

Day one complete! Bows backed, risers glued up, everything looked great! Good work guys!

Day Two

Day two began with trimming silk, then back to the sanders. Sanding and shaping and shaping and sanding.Tips were added to the bows for aesthetics and strength. We went to lunch while these cured up.

Bellies cut next. then it was Tiller Time! Sanding and shaping, then to the tiller trees.

More shaping, more tillering, more shaping, more tillering. The guys worked hard. The second casualty of the build was Davids bow, which was tillering beautifully and was nearly at his weight and draw length when it developed a nasty stress crack right near the riser. No way to predict it, it just happens sometimes. Ah well. Fortunately I had been building a bow along side them as a demo bow, and David took over the tillering on that, once again doing exceptional work and tillering out a beautiful bow.

Handles were shaped and arrow windows cut in. And then the best part of any bow build - Shooting the first arrows!

Chad's first shot! Nice tiller, really well made bow. 30# at 27". Good work Chad!

David's first shot! He essentially tillered two bows that day, and did a splendid job on both! Fortunately the back up bow turned out awesome as well - no stress cracks! 40# at 30". Excellent bow!

Two newly minted bowyers and their bows. Job well done, gentlemen! And you have a fine bow that you built yourself!

The obligatory full draw shot. Nice tillering guys!

It was a fun weekend of bow building! If you are interested in setting up a bow build weekend for your group, feel free to contact me for details! john@bluefeathergardens.com

More Later